Key to digital transformation focused on

the safety of factory and reliability of facility

Plant Digital Transformation (DT) Consulting

- Site/drawing (P&ID) matching, ISO, document and facility management consulting

- P&ID standardization

- Plant-centric system development

DT Project (System, Engineering)

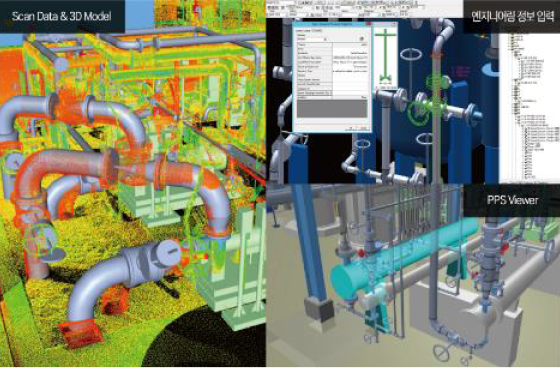

- Laser scan-based P&ID matching and standardization

- Master data standardization (facility, piping, document fault data, checklist)

- Document digitalization and OCR

Provision Of DT Solution

- Provision of an integrated plant portal package for management of documents, changes and work permits

Reliable by Using A Verified Standard Process

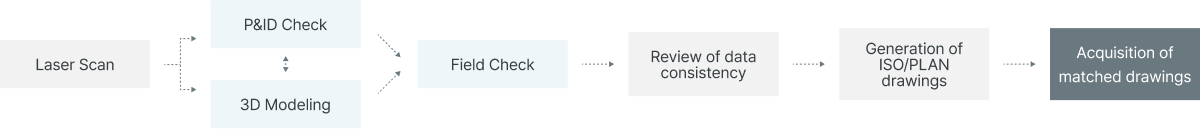

We match sites with drawings based on laser scan and technical materials using a verified reverse engineering methodology to prevent a delay in the process of checking drawings and decline in the efficiency therefrom.

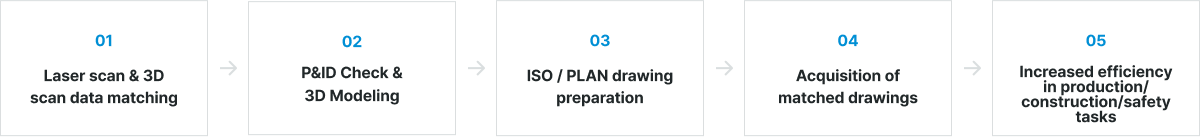

Reverse Engineering & Site/Drawing Matching Steps

Reverse Engineering & Site/Drawing Matching Process

We perform laser scan on the entire place of a factory, match scan data, generate P&ID drawings and ISO/PLAN drawings and produce drawings that match sites by applying a methodology that is verified through our experiences in the nation’s first reverse engineering project.

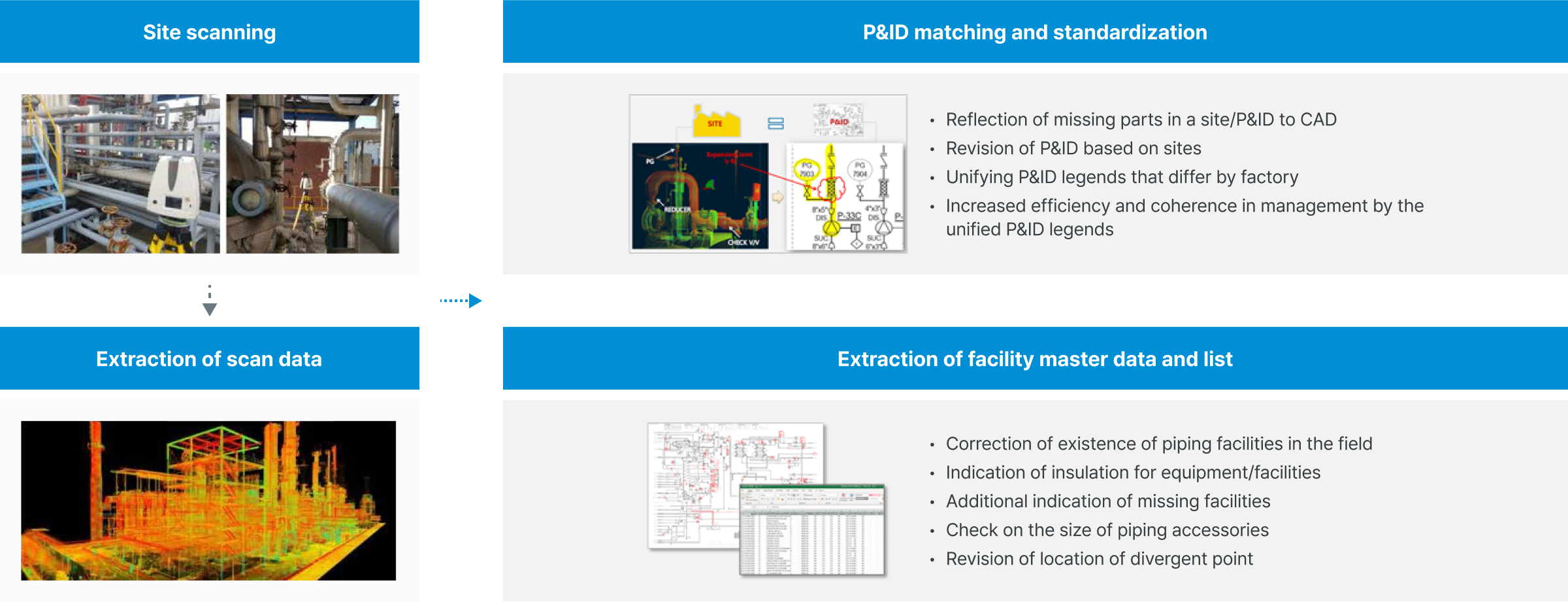

Effect Of Site/Drawing Matching

When the drawings of a site are brought to match the site using laser scan data, the coherence of technical materials can be increased without requiring the use of a 3D model, and master data and list for facility management can be extracted.

Reliable By Using A Verified Standard Process

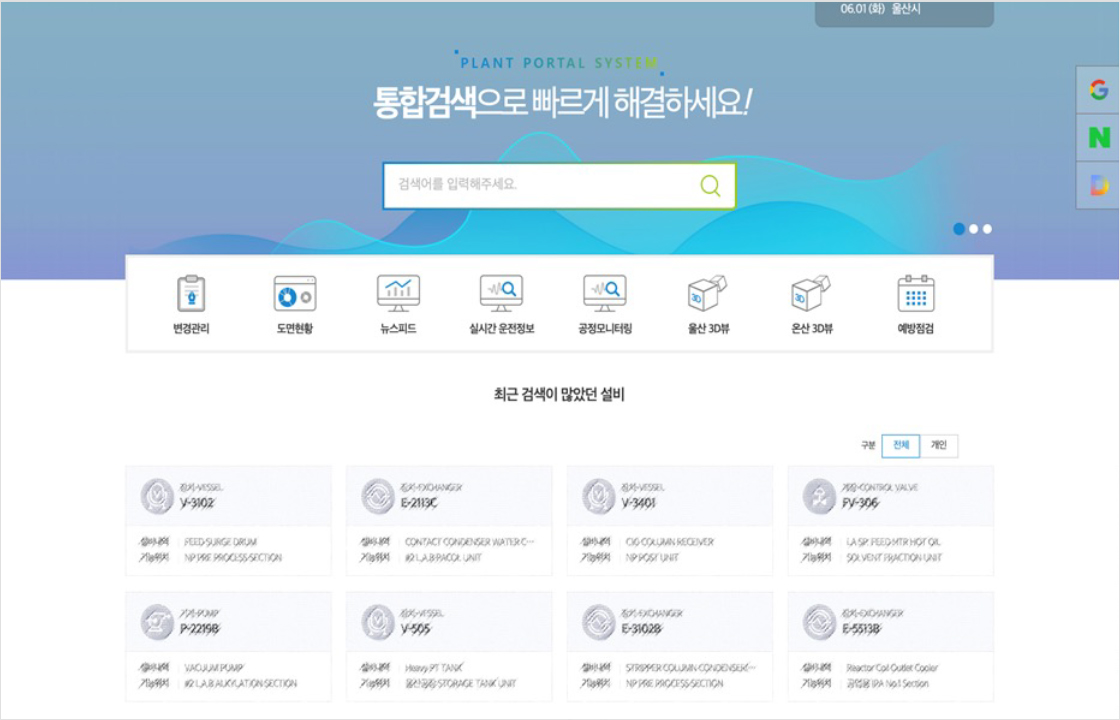

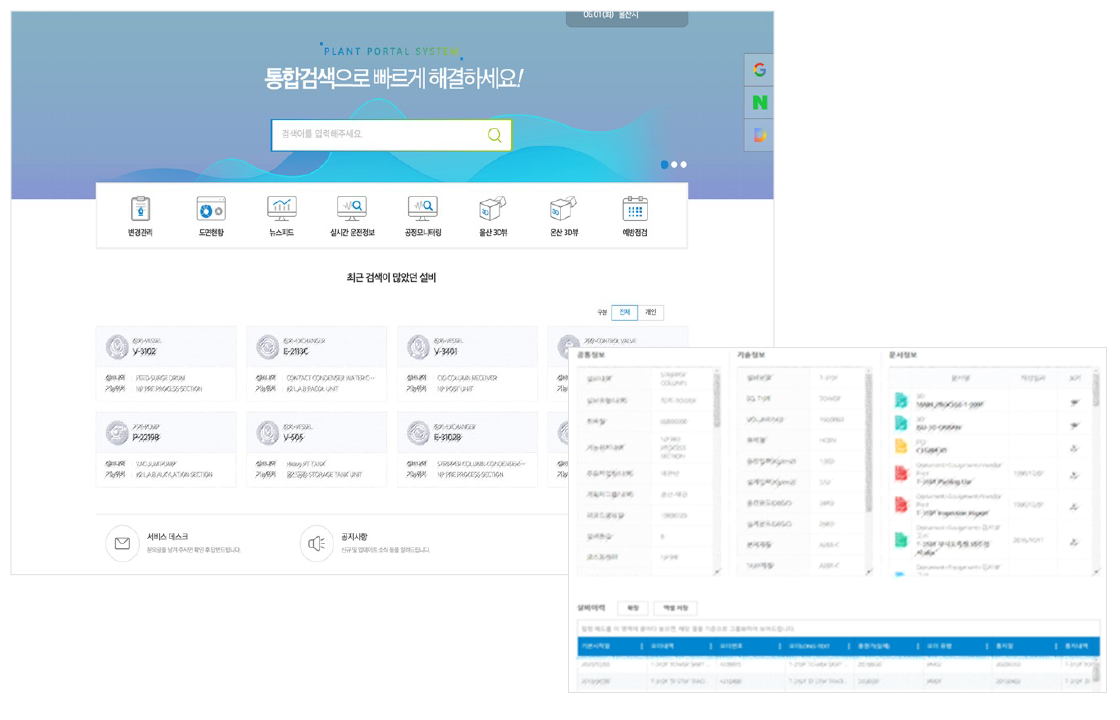

Integrated Plant Portal Solution Development Process

System Function

The plant portal provides information necessary for work by connecting systems necessary for operation and maintenance of factory.

Facility search

Document search

MOC search

Main facilities

Document search

MOC search

SAP connection

EDMS connection

Groupware/HR connection